Carefully select raw materials. Usually, high-quality galvanized steel or stainless steel plates are preferred. Galvanized steel plate has a relatively low cost, and the galvanized layer on the surface can effectively prevent rust and extend the service life of the garbage bin. Stainless steel plates have stronger corrosion resistance and are suitable for places with extremely high durability requirements and harsh environments, such as beaches and chemical parks.

Trash Can

Outdoor Trash Can |

Outdoor Trash Can |

Indoor Trash Can |

Indoor Trash Can |

Garbage Classification |

Garbage Bins And Smoke Exhaust Columns |

Circular Trash Can |

Mass Production |

Premium ProductsEngineered for quality, built for durability, finished with professional excellenc. |

Total CustomizationTailor size, materials, colors & design. We deliver exactly what you envision. |

Smart Value PricingPremium quality without premium costs. Maximize your budget impact. |

White-Glove Service10+ years expertise guiding your project from concept to delivery. Hassle-free partnership. |

Raw Material Selection

Cutting Technology

Accurate cutting is the key to ensuring the accurate size of metal trash cans. At present, laser cutting technology is widely used in the production of metal trash cans. Laser cutting has the advantages of high precision, smooth cutting, and small heat affected zone. It can quickly cut various complex shaped metal sheets, greatly improving production efficiency and product quality. For example, when making components such as side panels and top covers of trash cans, laser cutting can accurately cut different shapes and sizes according to design requirements, and the error can be controlled within a very small range. In addition, CNC plasma cutting is also a commonly used cutting method, which is suitable for cutting thicker metal sheets, with relatively low cost and certain advantages in large-scale production.

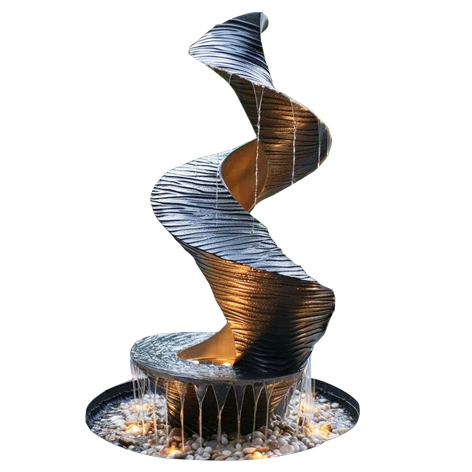

Forming Process

Usually, a curling machine is used for curling and forming. The plate rolling machine can roll flat metal plates into circular or elliptical barrels according to a predetermined curvature. During operation, the diameter and height of the barrel can be precisely controlled by adjusting the parameters of the plate rolling machine. At the connection between the barrel body and the barrel bottom, welding technology is generally used. The commonly used welding methods are resistance welding and argon arc welding. Resistance welding can achieve efficient and fast welding, with high weld strength; Argon arc welding is suitable for stainless steel trash cans that require high welding quality. It can ensure that the weld seam is beautiful, firm, and will not affect the corrosion resistance of the stainless steel material. For the top cover of the garbage bin, the stamping process is generally used.

Anti-Corrosion Treatment

In order to further improve the corrosion resistance of metal trash cans, surface anti-corrosion treatment is crucial. In addition to the anti-corrosion properties of galvanized steel plates mentioned earlier, surface treatment methods such as painting and spraying are usually used for garbage bins made of other metal materials. The spray painting process is simple, cost-effective, and can form a uniform paint film on the metal surface, which can isolate air and moisture and prevent metal rusting. Spray coating is the process of attaching plastic powder to a metal surface through electrostatic adsorption, and then curing it at high temperatures to form a strong plastic coating. The surface of the sprayed garbage bin has better wear resistance, corrosion resistance, and decorative properties, with a variety of colors that can meet the aesthetic needs of different places.

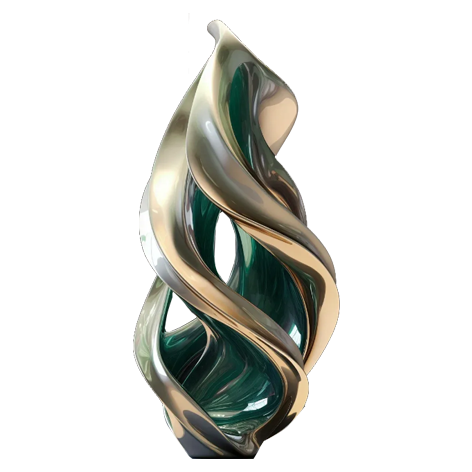

Decorative Treatment

In some places with high aesthetic requirements, metal trash cans will also undergo additional decorative treatment. For example, using screen printing technology to print various patterns, logos, or promotional slogans on the surface of garbage bins not only has practical functions, but also becomes a scenic line in the urban environment. In addition, for some high-end metal trash cans, electroplating, polishing and other processes are also used to give the surface of the trash can a bright metallic luster and enhance its overall texture.