Using laser cutting, plasma cutting and other technologies, accurately cut stainless steelplates according to the design pattern, and then assemble them. This process has highprecision and can achieve complex geometric shapes.

Corten Steel Sculptures

Three Sided Wall Weather Resistant Steel |

"Slanting Arc" Weathering Steel |

"Twisted Ellipse" Weathering Steel |

Grass Arc Line Weather Resistant Steel |

Dandelion Wall |

Water Feature wall |

Tree of Life Weathering Steel |

Imitation Of Wooden Strips Stacked With Weather Resistant Steel |

Premium ProductsEngineered for quality, built for durability, finished with professional excellenc. |

Total CustomizationTailor size, materials, colors & design. We deliver exactly what you envision. |

Smart Value PricingPremium quality without premium costs. Maximize your budget impact. |

White-Glove Service10+ years expertise guiding your project from concept to delivery. Hassle-free partnership. |

Cutting Process

Forging Process

First, make a mold according to the design drawing, heat the stainless steel plate to theappropriate temperature, then use tools such as air hammers to forge the approximateshape on the mold, and finally finely trim it. This technique can make the sculpture linessmooth and have a unique texture.

Casting Process

First, make the clay draft of the sculpture, then turn it intoa plaster or silicone mold, andthen cast it into a stainless steel sculpture using the lost wax method. It is suitable forcreating works with complex shapes and rich details.

Welding Process

Cut stainless steel plates or pipes into the desired shape, and then connect themtogether using welding equipment to form the overall structure of the sculpture. Thisprocess has high flexibility and can produce various large and abstract sculptures.

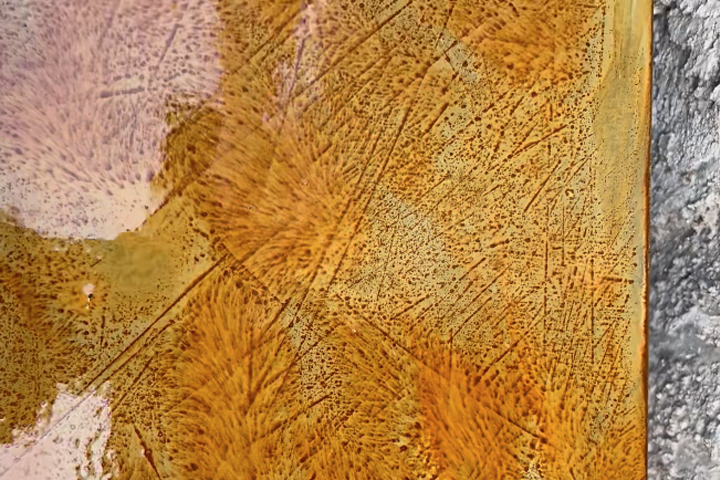

Stabilize Rust Layer+Special Coating

When treating with weather resistant film, the bottom layer is first treated with a weather resistant bottom film, forming an inorganic composite salt film mainly composed of composite phosphate on the surface of the weather resistant steel; Then, acrylic coating is applied on the composite salt film to form a porous grid coating with good breathability and permeability. The main function of weather resistant bottom film is to form a uniform and dense stabilizing rust layer on the surface of weather resistant steel. The upper porous grid coating can allow a certain amount of air and water to be supplied to the bottom layer until it forms a stable rust layer, while also preventing the flow and scattering of rust solution in the early stages of use, maintaining a beautiful appearance. After the formation of the stabilized rust layer, this coating gradually disappears, and there is no significant change in appearance at this time. But the time of stable rust layer changes is closely related to the environment.